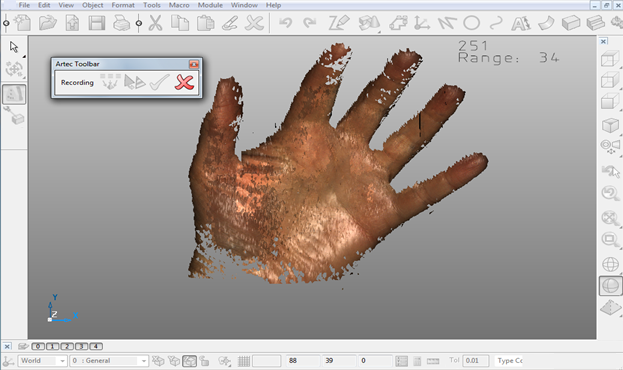

Answer some simple questions about the object you have scanned and Artec’s advanced 3D imaging software will select the most effective 3D algorithms for your data and will develop a high precision model ready for use in your professional application. New to Artec Studio 11 is Autopilot, an advanced smart mode which guides users through 3D scanning and data processing in a few easy steps. Stratasys J750 Digital Anatomy 3D Printer.

#ARTEC STUDIO 11 FORUM FREE#

AESUB Blue is free of pigments while AESUB White is pigment-based but is FREE of titanium dioxide nanoparticles (TiO2). All our AESUB products are free of harmful titanium dioxide. AESUB 3D scanning sprays are less toxic compared to similar sprays in the market. The challenging surface is covered so it doesn’t cause issues during scanning and it creates the ideal 3D scanning surface.Īs you can see from the example of 3D scanning a motorcycle helmet, using a developer spray (also known as 3D scanning spray) drastically improves results.Īt our lab, we currently use AESUB 3D scanning spray to coat parts for 3D scanning specifically developed by 3D scanning experts. In those cases, you will need to spray the part with a matte opaque coating to cover the surface. There are some extreme cases (especially clear surfaces) when your 3D scanner is unable to scan properly even when you have the most ideal scanner settings.

Before you try other methods, see if your 3D scanner’s settings can be adjusted to scanning dark, shiny, or transparent parts.Įach scanner will be different but usually adjusting the exposure settings helps to compensate for the object’s surface characteristics to create a better condition for scanning. Some 3D scanners are pretty good at adapting to surface variations. Transparent surfaces such as glass or clear plastic Metals such as chrome or steel, jewelry, mirrored surfaces, any reflective parts Light scatters and bounces in uncontrollable directions When scanning these challenging surfaces, it causes the following interference: Surface Type They affect how the 3D scanner views the object and consequently affect how it takes the images. While 3D scanners are great at capturing most surfaces, some types of surfaces cause the light to be distorted in such a way that it interferes with the data acquisition process.

Why Do Dark, Shiny, or Clear Surfaces Interfere with the 3D Scanning Process? A three-dimensional representation of the object after post-processing (View it in 3D)

0 kommentar(er)

0 kommentar(er)